BHA Inspections

Bottom Hole Assembly (BHA) inspections are carried out as per latest editions of API and DS-1 (3-5) guidelines. BHA inspections services include:

- Visual Inspections

- Thread Gauging

- Wet and Dry Magnetic Particle Inspection

- Dimensional Inspection

Optional service of refacing if required can be provided.

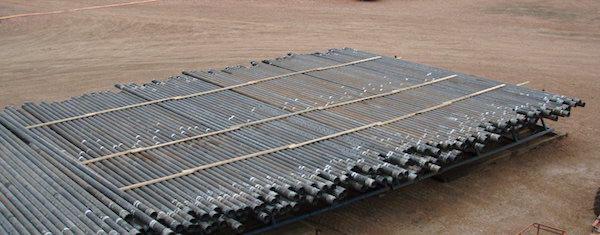

Casing and Tubing Inspection

Our inspections meet or exceed API requirements, follow documented Standard Operating Procedures and safety protocols. We inspect all casing & tubing sizes, pup joints.

Premium Connections / API Connections Inspection

We inspect all different premium Connections / API Connection

Visual Body Inspection

We perform visual inspection of ID and OD of all tubings and casings for obvious external damages such as external corrosion, dented, mashed, or bent tubes. Most damages arise from handling of the tubular.

Visual Thread Inspection

We thoroughly clean and visually inspect and evaluate both pin and box end connections for any damages, such as pitted, cut or mashed seals, galled threads, corrosion, coating integrity, etc. Any defects noted will be clearly marked on the area and identified on the inspection report.